A timing belt tensioner is a device that applies precise force against the engine’s timing belt to prevent slipping and maintain accuracy of the valve and piston timing.

At its core, it uses a calibrated spring and a smooth-rolling pulley to supply steady 300 to 400 pound tension against the belt. This force creates friction so the belt’s teeth stay engaged in their sprockets, preventing potentially catastrophic timing skips while also reducing wear. The tensioner’s pivoting arm and high quality bearings enable it to smoothly adjust for belt expansion and contraction.

By maintaining perfect timing belt tension, the tensioner enables optimal performance, efficiency, and service life from the engine.

This article explores the components of a tensioner, how it works to provide ideal constant tension, its benefits for the timing system, different types of tensioners, and symptoms of tensioner problems.

Components of a Timing Belt Tensioner

Knowing the parts of the timing belt tensioner is essential to understand its process. A timing belt tensioner consists of four main parts:

- Spring: The tensioner spring, typically a coil spring, supplies force against the tensioner pulley. The spring is calibrated to provide the precise tension required by the timing belt, usually between 300 to 400 pounds. Without proper spring tension, the timing belt could jump timing or wear prematurely.

- Pulley: The tensioner pulley has a smooth, rounded surface that contacts the timing belt. It is commonly made of plastic or metal and incorporates sealed ball bearings to reduce friction. The pulley diameter is designed to optimize grip and prevent slippage.

- Arm: The tensioner arm is mounted on a pivot and holds the pulley. It acts as a lever, transmitting force from the spring to create tension against the belt. The pivot design enables the arm to move and maintain consistent belt tension.

- Bearing: Enclosed ball bearings allow the pulley to spin freely with minimal friction. Quality bearings are essential for smooth, reliable operation over thousands of engine cycles.

How a Timing Belt Tensioner Works

The simple but ingenious design of a timing belt tensioner enables it to apply optimal force on the timing belt continuously over years of operation.

Here is how the components work together:

- The tensioner spring exerts force against the tensioner arm, pressing the pulley firmly against the belt with a force of 300 to 400 pounds. This constant spring pressure creates friction that prevents the timing belt from slipping.

- As the timing belt expands and contracts with temperature changes, the tensioner arm pivots on its axis. This allows the pulley to move slightly back and forth, automatically adjusting tension to maintain the optimal level.

- The tensioner bearing allows the pulley to roll smoothly against the timing belt. This dramatically reduces friction, preventing heat and wear. The bearing must spin freely for the tensioner to function properly.

- Together, the spring, pivoting arm and smooth bearing maintain continuous, consistent tension of the timing belt. This prevents skips, slips, or vibrations that could damage the engine. The tensioner thereby enables precision engine timing day after day, year after year.

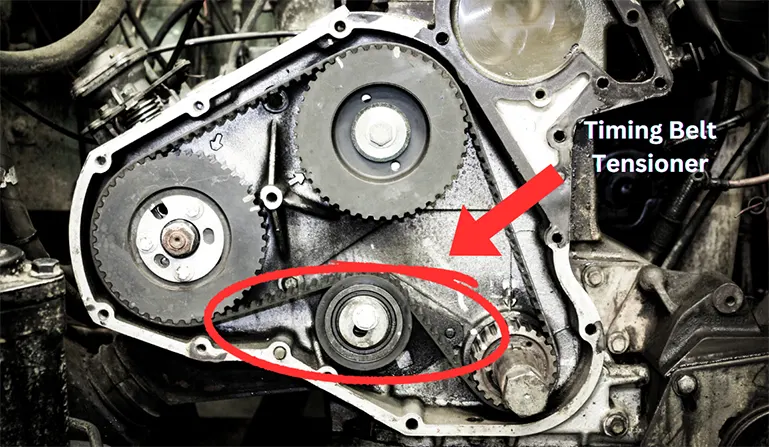

The below image shows how the Timing Belt Tensioner looks like when it separates from the engine.

Look at the below image. It helps you to easily identify the Timing Belt Tensioner on the car engine.

Benefits of a Timing Belt Tensioner

Correct timing belt tension is critical for proper engine operation. Here are the key benefits provided by a timing belt tensioner:

- Prevents timing belt slippage – The tensioner supplies friction to grip the belt, preventing the teeth from jumping or slipping, which could throw off valve timing.

- Reduces belt and engine wear – Without proper tension, a timing belt whips, flogs, and abrades. This causes cracks and deterioration. Proper 300 to 400 pounds of tension prevents damage from slack or oscillations.

- Absorbs shock – The pivoting arm dampens and absorbs vibrations and engine torsional movements that could otherwise be transmitted to the timing belt. This prevents traumatic shocks to the belt and engine components.

- Maintains timing accuracy – By preventing slippage and controlling dynamics, the tensioner enables consistently precise valve/piston timing. This maximizes power, efficiency, and emissions.

- Compensates for stretch and thermal expansion – As the timing belt naturally stretches from wear and heats up from engine operation, the tensioner automatically adjusts to maintain perfect tension.

Types of Timing Belt Tensioners

There are two main types of tensioners used for timing belts:

- Automatic Tensioners: These use spring-loaded arms that pivot and constantly adjust tension. This self-regulating design does not require manual tensioning maintenance. Automatic tensioners are preferred for their convenience and reliability.

- Manual Tensioners: Manual tensioners must be periodically adjusted by rotating the tensioner mounting bolts to move the pulley. They allow tension to be measured and set to specifications. However, maintaining proper tension requires regular re-tightening as the belt stretches.

Most modern engines use automatic tensioners. However, manual tensioners are still found on some older engine designs.

Common Problems with Timing Belt Tensioners

Like any mechanical component, timing belt tensioners are subject to wear and potential failure. Here are some common problems to look out for:

- Broken or weakened tensioner spring – This allows the belt to lose tension, potentially causing slippage and catastrophic timing failure. Springs may fatigue from age and exposure to heat cycles.

- Seized or worn tensioner bearing – Lack of free pulley movement prevents the tensioner from adjusting. This accelerates belt wear and can lead to failure.

- Bent or damaged tensioner arm – The arm may be bent by engine interference or wear. Any loss of proper geometry inhibits smooth tensioner function.

- Detached or cracked tensioner pulley – If the pulley separates or cracks, it can no longer apply controlled tension to the timing belt.

Regular inspection and replacement of aging tensioner components is crucial to avoid disruptive belt failures, which often result in bent valves and piston damage when the engine loses synchronization.

How do I know if my timing belt tensioner is bad?

- Listen for unusual noises coming from the timing belt area.

- Check for a loose or slipping timing belt.

- Look for any signs of wear or damage to the tensioner.

- If you experience any drivability issues, such as misfires, loss of power, or bucking, it’s possible that your timing belt tensioner is bad.

How does a belt tensioner pulley work?

A belt tensioner pulley is a spring-loaded pulley that keeps the timing belt tight. It does this by applying pressure to the back of the belt. When the belt starts to wear or stretch, the tensioner pulley automatically adjusts to keep it tight.

John Smith, a Los Angeles-based car specialist and automotive writer, boasts over 20 years in the industry. With a background as a master technician and a decade-long writing stint at notable automotive publications, John now shares his expansive knowledge on CarFinite, simplifying car maintenance for readers.