The main function of the head gasket is to seal the combustion chambers and prevent leaks between the engine block and cylinder head. Constructed as a multilayer steel or composite gasket, it endures tremendous pressures and heat to maintain the separation of oil, coolant, and combustion gases. Proper installation and torque techniques are critical, as head gasket failure can lead to coolant and oil leaks, compression loss, and engine overheating.

This article will discuss how modern head gaskets are designed and installed to handle their demanding role. We’ll cover the construction materials used, symptoms of a failing gasket, causes of failure, and the complexity of replacing a head gasket.

Functions of a Head Gasket

The head gasket serves several critical purposes:

- It creates a tight seal around the combustion chambers, preventing gases from escaping. This allows the air-fuel mixture to be properly compressed and combusted. The head gasket must withstand intense heat and pressure from exploding gases during engine operation.

- It prevents engine coolant and oil from mixing together or leaking externally. Coolant passages and oil galleries in the engine block and cylinder head must be separated and sealed.

- It maintains proper engine compression. Gasket failure can cause compression loss, resulting in poor performance and emissions. Proper sealing is required to reach the high compression ratios of modern engines.

Construction of a Head Gasket

Head gaskets were traditionally made of copper, but modern designs utilize various materials and sophisticated construction:

- Most are multi-layer steel gaskets, with layers of embossed and perforated steel shims covered by sealing coatings. Stainless steel offers high strength and heat resistance.

- Soft-facing materials like copper or aluminum are applied to areas sealing coolant and oil. This allows the gasket to conform to imperfect surfaces.

- High-performance engines often use multi-layer steel (MLS) gaskets. These use 3-5 layers of embossed and coated steel, allowing excellent sealing under high temperatures and pressures.

- Graphite is another common gasket material thanks to its heat resistance and conformability. However, it is prone to blowing out under high boost pressures.

- Many gaskets have silicone or rubber coating beads around combustion chamber holes to improve sealing. Some include steel, aluminum, or copper combustion sealing rings.

- Holes and grooves are designed to direct oil and coolant to proper passages while blocking potential leak paths. Precise embossing patterns allow tight sealing.

Installation of a Head Gasket

Proper head gasket installation is crucial to avoiding leaks and failure:

- Start by ensuring the cylinder head and block mating surfaces are clean and flat. Surface irregularities can cause leaks. A thin scraper can remove old gasket material.

- Carefully place the new head gasket aligned with the block. Use masking tape to hold it in position if needed. Ensure it sits flat with no folds or wrinkles.

- Apply torque to head bolts in the proper sequence and increments, typically working from the middle outwards. This allows even clamping. Torque values will range from 65-100 ft-lbs depending on the engine.

- Always follow factory torque specifications found in service manuals. Use a calibrated torque wrench to ensure accuracy. Uneven or improper torque can lead to leaks.

Symptoms of a Faulty Head Gasket

Some common signs of head gasket failure include:

- Engine overheating from combustion gases leaking into the cooling jacket. This leads to coolant loss and inadequate cooling.

- White exhaust smoke, especially at startup. This indicates combustion gases are leaking into the coolant and being burned off through the exhaust.

- Milky, beige oil caused by coolant mixing with engine oil. Coolant leaks into the crankcase through the failed gasket.

- Low compression in one or more cylinders due to gasket leaks. This causes overall poor performance.

- Bubbling in the radiator or coolant overflow tank from exhaust gases entering the cooling system.

Causes of Head Gasket Failure

Typical reasons for a head gasket to fail include:

- Engine overheating – Extreme temperature weakens the gasket over time, leading to breakdown of sealing materials and layers.

- Excessive wear and tear – High mileage engines naturally degrade gasket sealing effectiveness after years of thermal cycling.

- Improper installation – Incorrect torque procedures, misalignment, or contaminated surfaces prevent proper sealing.

- Mechanical issues – A cracked block or head, warped surfaces, or damaged head bolts can cause leaks or blowouts.

- Design flaws – Some gaskets are prone to leakage on certain engines. Upgrading to a multi-layer steel style often solves chronic issues.

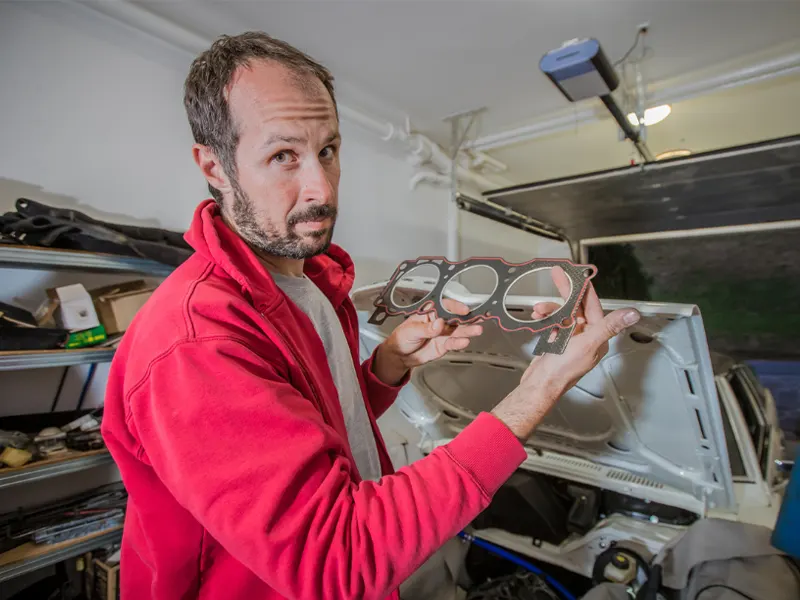

Replacing a Head Gasket

- Replacing a head gasket is one of the most complex and labor-intensive repairs on any engine. It typically requires 20-40 hours of shop time and often costs over $1000.

- The engine must be partially disassembled to remove the cylinder head. The head bolts, valve train components, intake, exhaust, and timing drive must first be removed.

- Once separated, the head and block surfaces must be inspected and checked for warpage. Warped surfaces may need machining. Sealing surfaces must be perfectly clean.

- The new gasket must be precisely aligned and installed using proper torque techniques. All components must be re-assembled and timing precisely set.

- Due to the specialized skills and tools required, this job is best left to professional technicians. Head gasket replacement is crucial to restoring engine performance and preventing further damage.

What is the head gasket in simple terms?

The head gasket is a multilayered mechanical seal that sits between the engine block and cylinder head, sealing the combustion chambers.

Where is the head gasket located?

The head gasket is located between the engine block and the cylinder head. It seals the joining surface between these two critical engine components.

John Smith, a Los Angeles-based car specialist and automotive writer, boasts over 20 years in the industry. With a background as a master technician and a decade-long writing stint at notable automotive publications, John now shares his expansive knowledge on CarFinite, simplifying car maintenance for readers.