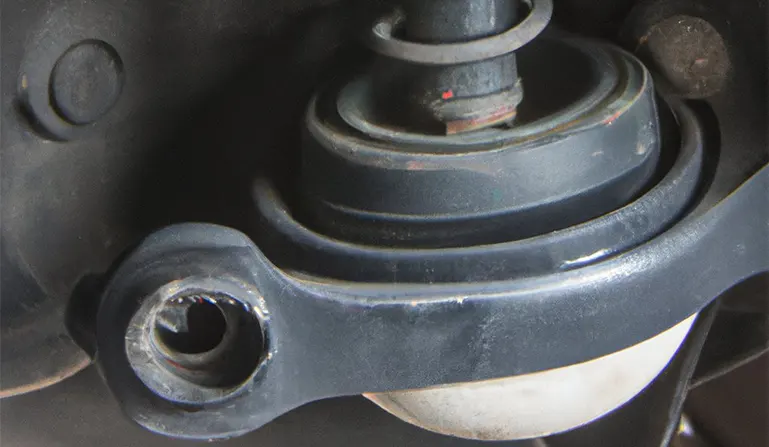

A ball joint is a type of hinge that connects the control arm of a vehicle’s suspension to the steering knuckle. It allows for both rotational and vertical movement, which is necessary for the suspension to absorb bumps in the road and for the wheels to steer properly.

Ball joints are typically steel and coated with a protective layer to prevent rust and wear. Over time, ball joints can wear out and become loose, which can cause steering problems and poor suspension performance. It is important to have a mechanic inspect your ball joints regularly to ensure they are in good condition and to prevent costly repairs down the road.

What are ball joint types?

| Ball Joint Type | Description | Commonly Found In |

| Press-in | Most common type of ball joint, is installed by pressing it into the steering knuckle using a press tool. | Most vehicles |

| Screw-in | Also known as threaded ball joints, designed to be more durable than press-in ball joints, typically found in heavy-duty and performance vehicles. Installed by screwing them into the steering knuckle using a special tool. | Heavy-duty, performance, and off-road vehicles |

| R-Joint or Rzeppa Joint | Hybrid between press-in and screw-in joints uses a tapered pin to keep the joint in place for increased durability and adjustability. | High-performance vehicles and racing applications |

What are the symptoms of bad ball joints?

Loose steering

If the ball joints are worn, they can become loose and cause the steering to feel loose or “sloppy.” This can make it difficult to keep the vehicle in a straight line and can be dangerous while driving.

Uneven tire wear

Worn ball joints can also cause uneven tire wear, as the suspension will not be able to properly support the weight of the vehicle. This can lead to rapid tire wear and the need to replace tires more frequently.

Clunking or popping noise

Worn ball joints can create a clunking or popping noise when the vehicle is driving over bumps in the road. This noise is caused by the metal-on-metal contact between the ball joint and the steering knuckle.

Vibration in the steering wheels

If the ball joints are worn or damaged, it can cause vibration in the steering wheel while driving. This is because the ball joint is not allowing the suspension to properly absorb bumps in the road.

Misaligned wheels

Worn ball joints can cause the wheels to become misaligned, which can lead to uneven tire wear and problems with the steering and suspension.

It is important to have a mechanic inspect your ball joints regularly to ensure they are in good condition and to prevent costly repairs down the road.

Can I drive a car with a bad ball joint?

No, driving a car with a bad ball joint is unequivocally unsafe and not recommended. The ball joint, a pivotal component in the suspension system, connects the control arm to the steering knuckle, ensuring accurate and stable wheel movement.

When a ball joint is defective, it severely compromises vehicle stability and steering accuracy, potentially leading to a wheel collapse and a sudden loss of control, thereby elevating the risk of an accident.

Addressing a faulty ball joint promptly is imperative to prevent endangering driving conditions and to mitigate further damage to related suspension and steering components, ensuring that the vehicle maintains secure and stable driving dynamics.

How do I check my own ball joints?

Checking your own ball joints involves a systematic approach to ensure you accurately assess their condition and maintain safety. Here’s a step-by-step guide:

- Elevate the Vehicle: Safely lift the vehicle using a jack and ensure it is securely positioned on jack stands.

- Locate the Ball Joint: Identify the ball joint, typically found connecting the steering knuckle to the control arm.

- Visual Inspection: Examine the ball joint for visible signs of wear, corrosion, or damage, and inspect the rubber boot for any tears or leaks.

- Movement Check: Apply pressure to the wheel, attempting to move it side to side and top to bottom, observing for any unusual movement or sounds from the ball joint.

- Professional Consultation: Especially if wear or damage is detected, consult with a professional mechanic for a thorough assessment and necessary replacements.

How can we fix a ball joint issue?

There are several ways to fix a ball joint issue, depending on the severity of the problem:

- Replacement: If the ball joints are worn or damaged beyond repair, they will need to be replaced. This is the most common method of repair and involves removing the old ball joints and installing new ones. This process can be done with a press tool and requires a professional mechanic to perform the job.

- Greasing: If the ball joints are still in good condition but are making noise or feeling loose, they may just need to be greased. This process involves injecting new grease into the ball joint to help lubricate it and reduce noise.

- Adjustment: If the ball joints are not worn but the alignment of the wheels is off, an adjustment may be needed. This process involves adjusting the angle of the ball joint to align the wheels correctly.

- Ball joint Boot Replacement: If the ball joint is worn but the ball joint itself is still good, the boot around the joint may need to be replaced. This process involves replacing the rubber boot that protects the ball joint from dirt and debris, but it will not fix the internal wear of the joint.

It’s important to note that ball joint replacement is a complex task that requires specialized tools and professional knowledge. It is recommended to consult with a professional mechanic for the best results.

Additionally, If the ball joints are worn or damaged, it is important to have them replaced as soon as possible, as worn ball joints can cause other problems with your suspension and steering and can be dangerous while driving.

How much does it cost to replace a ball joint?

On average, the cost of a ball joint replacement can range from $150 to $400, with the average cost being around $300.

It’s also important to keep in mind that replacing ball joints can be a complex task that requires specialized tools and professional knowledge. It is recommended to consult with a professional mechanic for the best results.

What are ball joint replacement tools?

Several specialized tools are required to replace ball joints, including:

1. Ball joint press

This tool is used to press the old ball joint out of the steering knuckle and to press the new ball joint in place. It consists of a metal frame, several adapters, and a hydraulic ram.

2. Ball joint separator

This tool is used to separate the ball joint from the control arm. It is designed to fit between the ball joint and the control arm and is used to push the ball joint out of the socket.

3. Pickle fork

This tool is also called a ball joint separator and is used to separate the ball joint from the steering knuckle. It consists of a metal fork that is inserted between the ball joint and the steering knuckle and a hammer is used to tap the fork to separate the ball joint.

4. Impact Wrench

This tool is used to loosen and remove the nuts and bolts that hold the ball joint in place. It is a powerful tool that can make the job easier by saving time and effort. Here I have attached an image of a Impact wrench below.

5. Torque wrench

This tool is used to tighten the bolts and nuts that hold the ball joint in place, to the manufacturer’s specified torque. This ensures that the ball joint is properly secured and will not come loose while driving. Here I have attached an image of a Torque wrench below.

6. alignment tools

After the ball joint replacement, it is important to have a proper alignment to ensure the vehicle’s handling and safety. The alignment tools include a camber gauge, caster gauge, and toe gauge.

Summary

The article on CarFinite provides a detailed exploration of car ball joints, highlighting their critical role in ensuring smooth wheel movement and vehicle stability. It outlines the notable symptoms and risks of driving with a defective ball joint, offers a step-by-step guide for checking their condition, and discusses various repair methods, costs, and necessary tools for replacement. The guide serves as a comprehensive resource for understanding, diagnosing, and addressing ball joint issues effectively.

For more valuable facts and insights about car maintenance and other related topics, explore our CarFinit Blog.

John Smith, a Los Angeles-based car specialist and automotive writer, boasts over 20 years in the industry. With a background as a master technician and a decade-long writing stint at notable automotive publications, John now shares his expansive knowledge on CarFinite, simplifying car maintenance for readers.